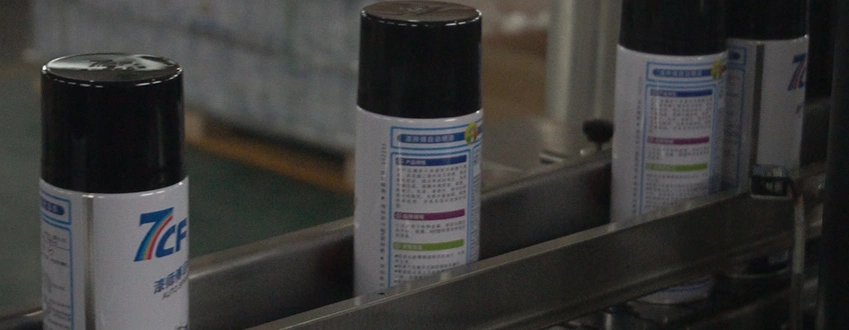

7CF® Cold Galvanizing Compound provides high-efficiency anti-corrosion protection, using high-purity zinc powder, combined with the dual advantages of electro-galvanizing and zinc coating, to achieve galvanizing effect by non-electroplating process; it has better cathodic protection ability than ordinary zinc-rich compound, combined with good barrier protection function to obtain excellent long-term anti-corrosion performance, good ability to adapt to harsh environments, convenient construction,without electroplating, to achieve galvanized.

96% pure zinc

High temperature resistance, moisture resistance, wear resistance

Excellent weldability, not easy to peel off

No corrosion after 3000 hours salt spray resistance test

For long-term effective anti-corrosion of steel components and facilities, such as the protection of bridges, building steel structures, towers, containers, car bodies, pipes, signs, fences and other components;

For repairing and strengthening the damage of the protective layer which is caused by welding, riveting, cutting and other operations.

Surface treatment: Oil, dust and water should be removed completely from the surface to be coated.

Keep shaking the can for about two minutes to mix the material sufficiently and evenly , in case of clogging . Spray the paint about 20cm above the substrate repeatedly and evenly as needed.

For repairing , coating thickness depends on the extent of damage by spraying 2-3 times back and forth.

Turn the can upside down and press nozzle for few seconds to purge the valve until only gas comes out.

Physical and chemical properties | |||

Appearance: | gray liquid | PH: | 5-7 |

Relative density: (water=1) | 2.78 | Flash point (℃): | <0 |

Solubility: | insoluble in water | Explosiveness: | The raw material generally does not explode, but it can cause explosion when mixed in the air |

ITEM NO. | Container size | Optional sizes |

A-S-014 | 10oz(283g) | 8oz(226g), 9oz(255g) |

GET IN TOUCH WITH 7CF TO LEARN MORE PRODUCT LINES

English

English  Español

Español  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt